Mooring for Floating Offshore Wind

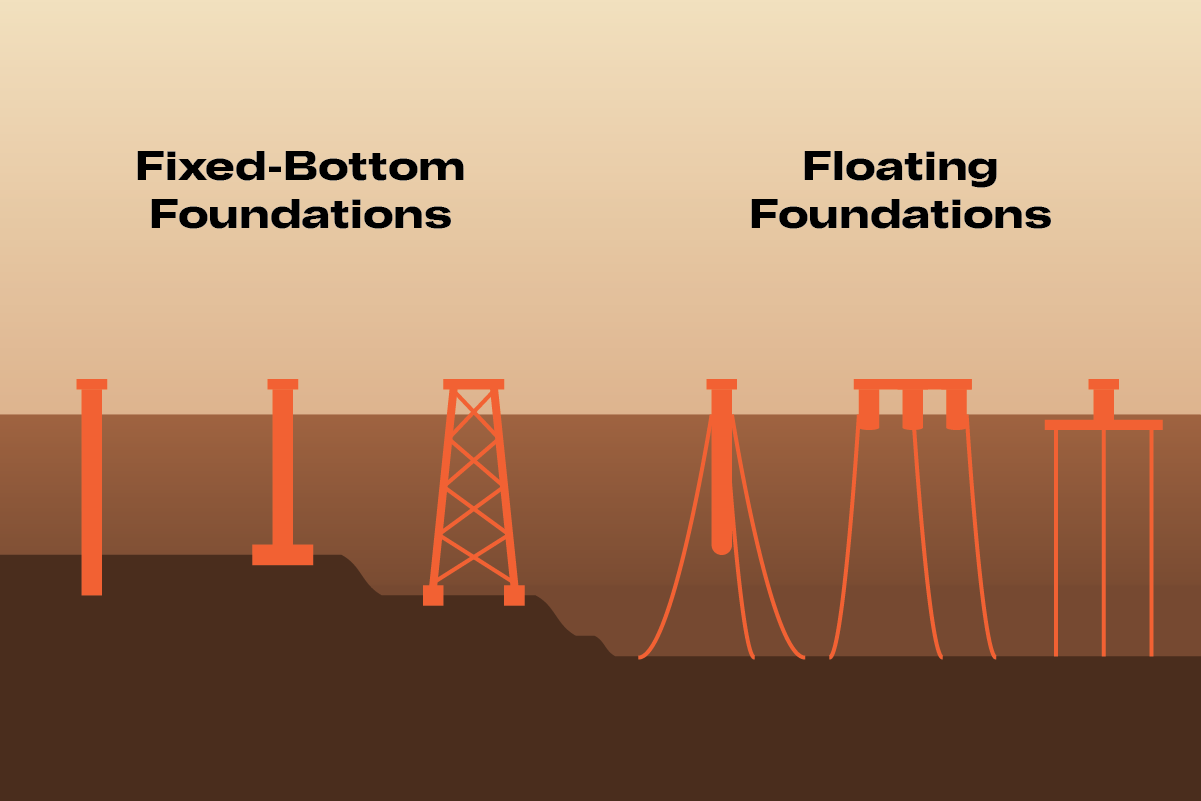

The 2 major types of offshore foundations are fixed-bottom & floating. Fixed-bottom make up the largest share of offshore wind however as water depths increase, fixed-bottom becomes less feasible. A key factor being an increase in cost and complexity in the construction.

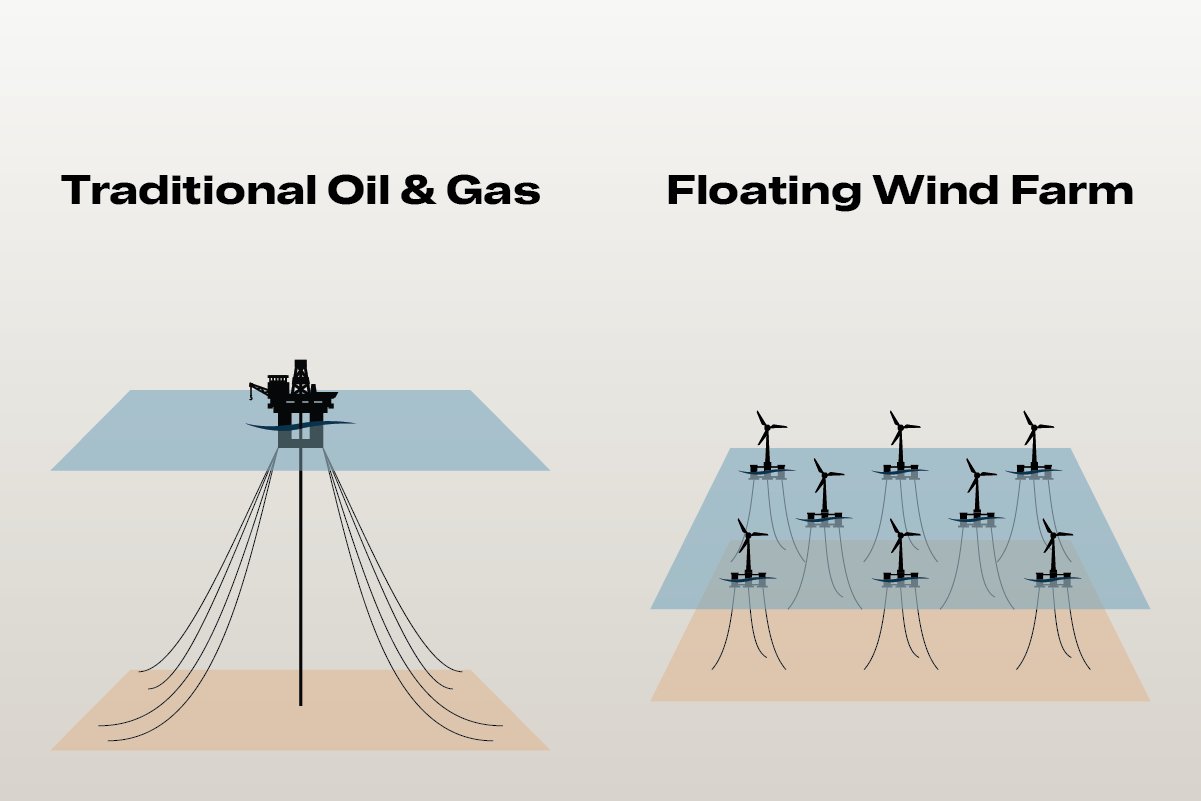

The opportunity for floating offshore wind (FOW) is in these greater water depths (>60m). FOW can also take advantage of the stronger and more consistent wind speeds, usually found in locations at these water depths. As of 2022 it is estimated there is over 200MW of floating wind power installed and online.