An association between Broken Hill Proprietary Co. Ltd. (BHP) and rope manufacturers in Great Britain led to the establishment in 1923 of a wire rope manufacturing facility in Newcastle. A new company was formed under the name, Australian Wire Rope Works.

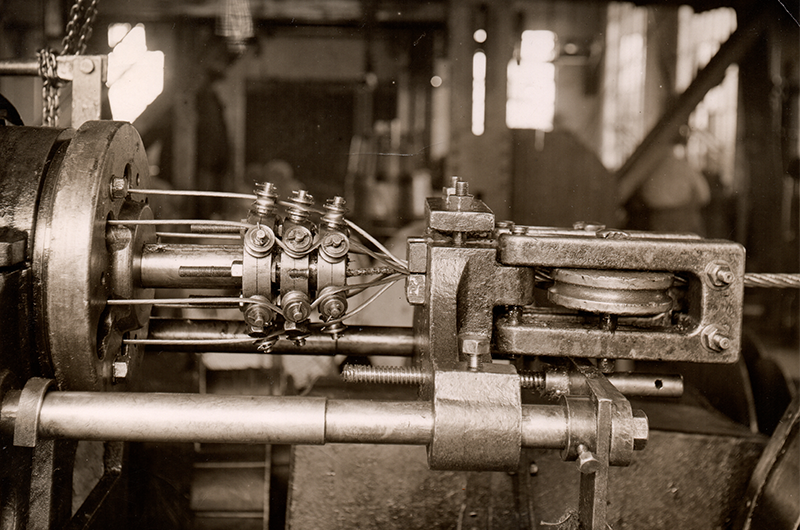

A site was selected in Newcastle, and a state of the art factory was built, with advanced manufacturing equipment, producing ropes compliant with British standards. Rope manufacturing began in 1925 and in 1933 the company became a fully owned subsidiary of BHP.

During the 1940s the rope works was upgraded to meet the needs of the defence and communication industries.

After 1945, Australia entered a boom period. The economy developed strongly and in the 1950s the Wire Rope Works was involved in major nation building projects such as the Snowy Mountains Scheme. In 1958, BHP consolidated and Australian Wire Rope Works became part of Australian Wire Industries (AWI). The 1970s and 1980s mining boom required new, advanced machines and additional capacity, with the capability to produce rope up to 150mm diameter, in 60 tonne parcels.

In 2000, the Long Products steel division separated from BHP and OneSteel was formed. Recognising the key role of the rope business, OneSteel began making strategic investments, such as the installation of one of the world’s largest electronically controlled rope closers in 2002, capable of producing 200mm diameter rope, and the installation of specialist plastic infusion equipment in 2009.

In July 2012, OneSteel, as a listed company, was renamed Arrium. Concurrently the rope business was rebranded as Moly-Cop Ropes, and we became part of the global mining consumables business of Moly-Cop. In March 2015 Arrium Limited sold its Wire Ropes business to Bekaert, a Belgium based company, specialising in wire products and coatings. MolyCop ropes was rebranded as WRI Australia, representing the brand used by the Bekaert Ropes Group businesses of Wire Rope Industries in North America, who themselves have over 125 years’ experience in wire ropes solutions for the mining and industrial sectors.