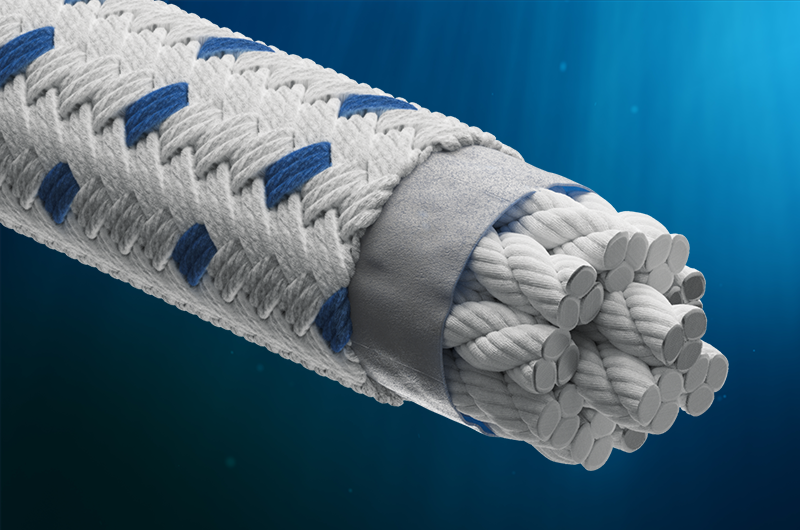

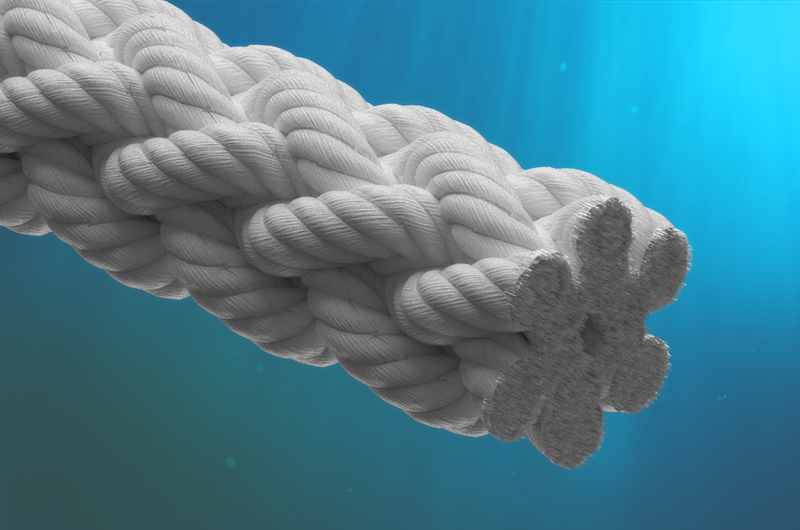

Synthetic Fibre Ropes

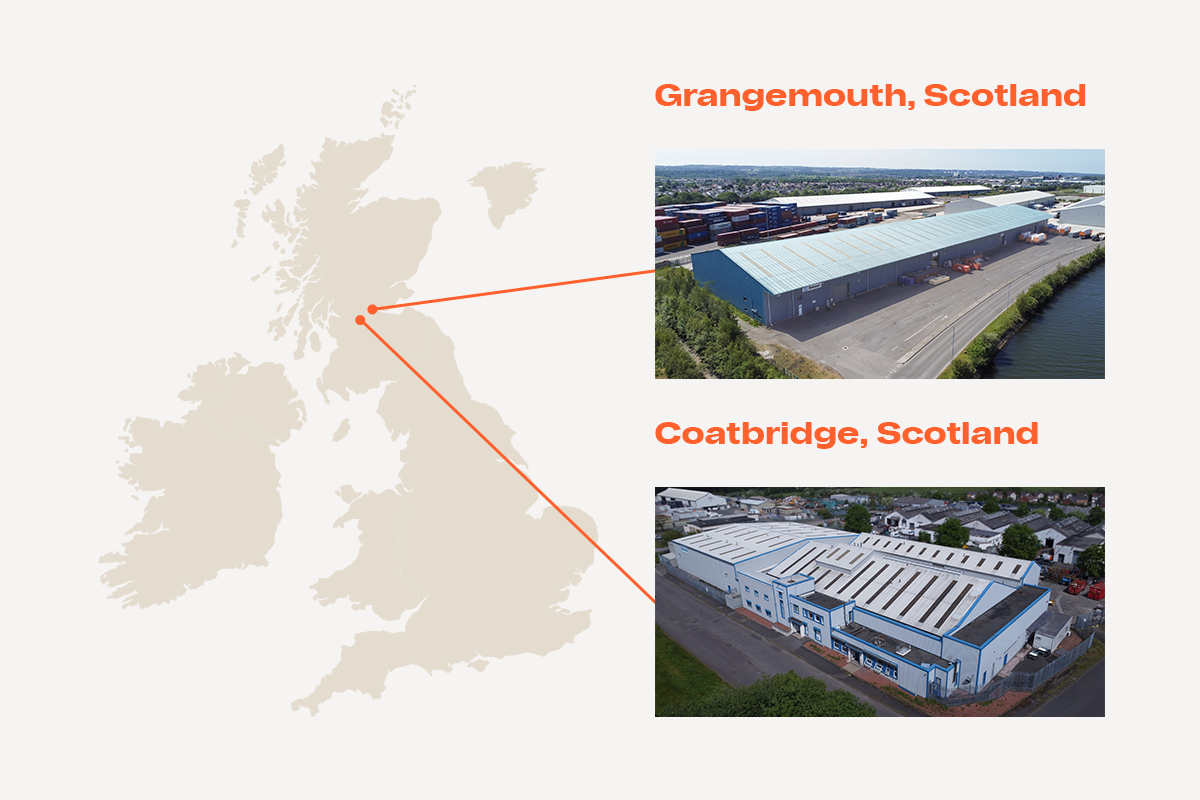

Bekaert are a world leading manufacturer of mission critical rope solutions. We are committed to supporting every client with solutions that answer the challenges of the industry.

A global leader in material science of steel wire transformation and coating technologies. Bekaert also have a combination of over 300 years of experience in steel wire and synthetic fibre ropes. Providing solutions to thousands of customers across the world. Our heritage, combined with a strong vision, purposeful goals and impactful leadership have made us world leaders in our field.