It is important that wire ropes being stored are adequately protected from the environment, windblown debris (sand, shot blast grit, etc.) and any hazards within the vicinity which could damage the rope. Care must also be taken to store/protect ropes from welding activities.

WARNING: Failure to comply with the following guidance could result in corrosion, loss of lubricant, contamination with harmful materials and foreign debris, damage etc. to the rope. Ropes which have deteriorated during storage could easily become unsafe to use.

All wire ropes being taken into storage must be clearly identified and accompanied with a manufacturers certificate.

Make sure that the rope is protected in such a manner that it will not be exposed to any accidental damage either during storage or when placing the rope in or taking the rope out of storage.

It is good practice to remove rope from the store on a ‘first in, first out’ basis to minimize the time held in storage.

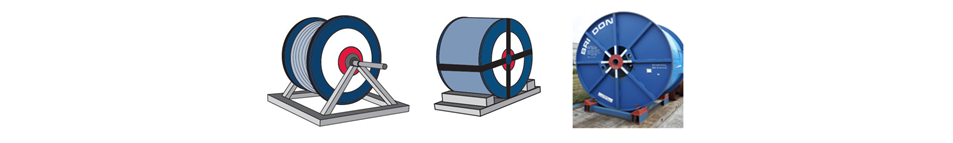

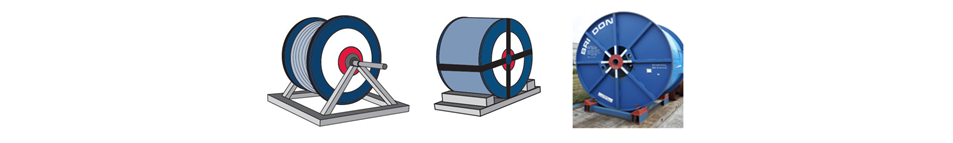

Wire ropes will generally be delivered on steel or wood reels or in coils. It is recommended that ropes supplied in coils, if not already, are placed and secured on pallets for subsequent handling and storage to minimize accidental damage. Wire ropes, where possible, should be stored with the rope clear of the floor, in a clean, dry, well ventilated, covered location, preferably within an air-conditioned warehouse. Ensure the floor or ground is level and capable of supporting the total mass of rope and reel. Bearers may be required to distribute the loading and all reels should be positioned and secured to prevent accidental uncontrolled movement.

WARNING: Failure to prevent reels from uncontrolled movement could cause damage to the rope and injury or death to personnel. If supplied on a reel without a cradle, the whole package may be supported on a simple frame or cradle that is located on the ground and is capable of supporting the total mass of rope plus reel, although most steel reels will be supplied on cradles

WARNING: Under no circumstances should the reel be lifted with the aid of the cradle, unless the cradle has been specifically designed, clearly identified, and rated that it may be used for lifting purposes.

Reels which have been supplied fully wrapped may suffer from a build-up of moisture/ condensation between the rope and the packaging material, which can result in corrosion and deterioration of the rope. In these situations, it may be necessary to replace or ventilate the packaging.

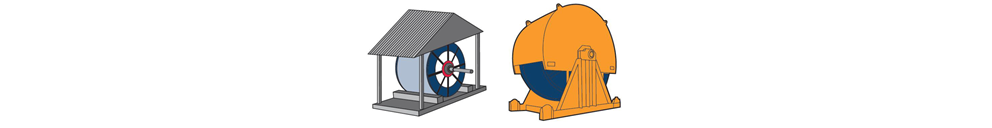

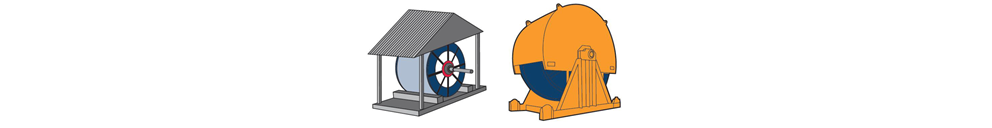

Where it is not possible to store the rope inside, the reel of the rope should be covered with a waterproof material or a suitable structure to protect from the sun and rain. To minimize the possibility of condensation being trapped between the rope and the packaging, the packaging should be ventilated to allow air to flow.

Coverings should be such that water drains away, so it does not become trapped within the covering, which may initiate corrosion of the rope.

Wire ropes in storage should not be exposed to temperatures above 90° C. Hence, where possible to optimise the service life of the rope, ambient temperatures should be maintained below 50° C.

WARNING: Properties of the rope may be affected, if the rope is stored for long periods at elevated temperatures e.g. none temperature controlled warehouse; bottom of mine shaft, etc.

For very large reels of rope, where storing undercover is not practical, the reels will have been supplied on a cradle and the reel should be covered particularly for long term storage, with special protective sheet/tarpaulin to provide protection from the sun, wind, rain, etc.

The picture illustrates packaging provided by Bridon-Bekaert where the wrapping on the supply reel is anchored to the cradle and open at the bottom. This provides ventilation and eliminates the build-up of moisture within the packaging, hence minimising the risk of corrosion. The packaging material can be supplied with reflective outer coating and/or insulated to aid temperature control.

It is considered good practice for wire ropes in storage to be routinely inspected (ideally every six months) and prior to being taken into use/service be inspected by a competent person for signs of damage/deterioration to either the rope or packaging. Reels stored for long periods particularly in warm environments and climates, if practical, may be rotated to minimize the migration of lubricant from the rope.

During inspection, if signs of migration and/or deterioration of the manufacturing lubricant are evident a suitable rope dressing which is compatible with the manufacturing lubricant should be applied. Contact Bridon-Bekaert or the rope supplier and follow the original equipment manufacturers instruction manual for guidance on recommended products or types of rope dressings, methods of application and equipment necessary to apply the dressing.

WARNING: Failure to apply the correct rope dressing can render the original manufacturing lubricant ineffective and reduce rope performance.

Further guidance is available at contact@bridon-bekaert.com

Reference: TB.001 Ed.1 Dec 2021

WARNING: Failure to comply with the following guidance could result in corrosion, loss of lubricant, contamination with harmful materials and foreign debris, damage etc. to the rope. Ropes which have deteriorated during storage could easily become unsafe to use.

All wire ropes being taken into storage must be clearly identified and accompanied with a manufacturers certificate.

Make sure that the rope is protected in such a manner that it will not be exposed to any accidental damage either during storage or when placing the rope in or taking the rope out of storage.

It is good practice to remove rope from the store on a ‘first in, first out’ basis to minimize the time held in storage.

Wire ropes will generally be delivered on steel or wood reels or in coils. It is recommended that ropes supplied in coils, if not already, are placed and secured on pallets for subsequent handling and storage to minimize accidental damage. Wire ropes, where possible, should be stored with the rope clear of the floor, in a clean, dry, well ventilated, covered location, preferably within an air-conditioned warehouse. Ensure the floor or ground is level and capable of supporting the total mass of rope and reel. Bearers may be required to distribute the loading and all reels should be positioned and secured to prevent accidental uncontrolled movement.

WARNING: Failure to prevent reels from uncontrolled movement could cause damage to the rope and injury or death to personnel. If supplied on a reel without a cradle, the whole package may be supported on a simple frame or cradle that is located on the ground and is capable of supporting the total mass of rope plus reel, although most steel reels will be supplied on cradles

WARNING: Under no circumstances should the reel be lifted with the aid of the cradle, unless the cradle has been specifically designed, clearly identified, and rated that it may be used for lifting purposes.

Reels which have been supplied fully wrapped may suffer from a build-up of moisture/ condensation between the rope and the packaging material, which can result in corrosion and deterioration of the rope. In these situations, it may be necessary to replace or ventilate the packaging.

Where it is not possible to store the rope inside, the reel of the rope should be covered with a waterproof material or a suitable structure to protect from the sun and rain. To minimize the possibility of condensation being trapped between the rope and the packaging, the packaging should be ventilated to allow air to flow.

Coverings should be such that water drains away, so it does not become trapped within the covering, which may initiate corrosion of the rope.

Wire ropes in storage should not be exposed to temperatures above 90° C. Hence, where possible to optimise the service life of the rope, ambient temperatures should be maintained below 50° C.

WARNING: Properties of the rope may be affected, if the rope is stored for long periods at elevated temperatures e.g. none temperature controlled warehouse; bottom of mine shaft, etc.

For very large reels of rope, where storing undercover is not practical, the reels will have been supplied on a cradle and the reel should be covered particularly for long term storage, with special protective sheet/tarpaulin to provide protection from the sun, wind, rain, etc.

The picture illustrates packaging provided by Bridon-Bekaert where the wrapping on the supply reel is anchored to the cradle and open at the bottom. This provides ventilation and eliminates the build-up of moisture within the packaging, hence minimising the risk of corrosion. The packaging material can be supplied with reflective outer coating and/or insulated to aid temperature control.

It is considered good practice for wire ropes in storage to be routinely inspected (ideally every six months) and prior to being taken into use/service be inspected by a competent person for signs of damage/deterioration to either the rope or packaging. Reels stored for long periods particularly in warm environments and climates, if practical, may be rotated to minimize the migration of lubricant from the rope.

During inspection, if signs of migration and/or deterioration of the manufacturing lubricant are evident a suitable rope dressing which is compatible with the manufacturing lubricant should be applied. Contact Bridon-Bekaert or the rope supplier and follow the original equipment manufacturers instruction manual for guidance on recommended products or types of rope dressings, methods of application and equipment necessary to apply the dressing.

WARNING: Failure to apply the correct rope dressing can render the original manufacturing lubricant ineffective and reduce rope performance.

Further guidance is available at contact@bridon-bekaert.com

Reference: TB.001 Ed.1 Dec 2021