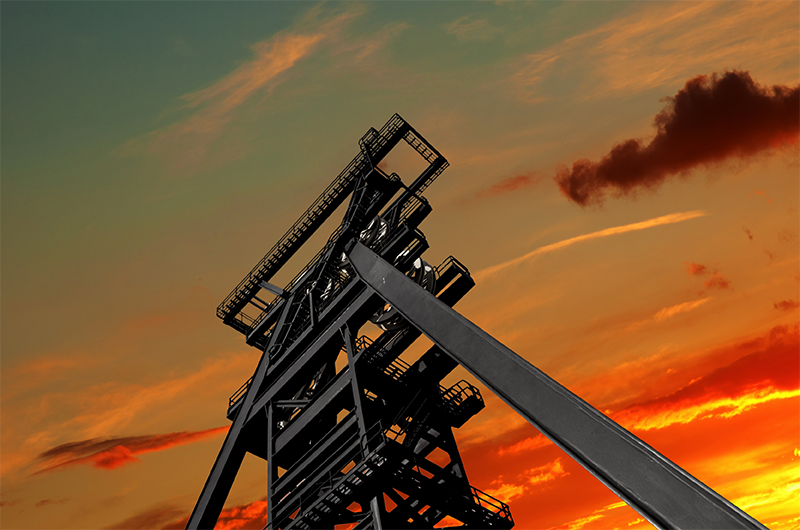

Underground mining

Underground mining

Each mine in the world is unique, starting with the mineral being mined and ending with the final hoisting of these minerals to the surface. The shaft hoisting is taking a key role in the underground mining processes. Each mine is hoisting minerals from different depths, and different loads each under unique shaft conditions.

Most mines are located in some of the harshest environments, the safety and reliability and the productivity of each shaft operation and in the mine depends to a great extent on a strong, efficient and safe hoisting setup, where the mining rope is playing a key role, which requires a constant improvement.

Bridon-Bekaert ensures a safe and efficient shaft operation through supplying customers with customised ropes according to the specific needs. Together with the right service on site to guarantee the maximum productivity.