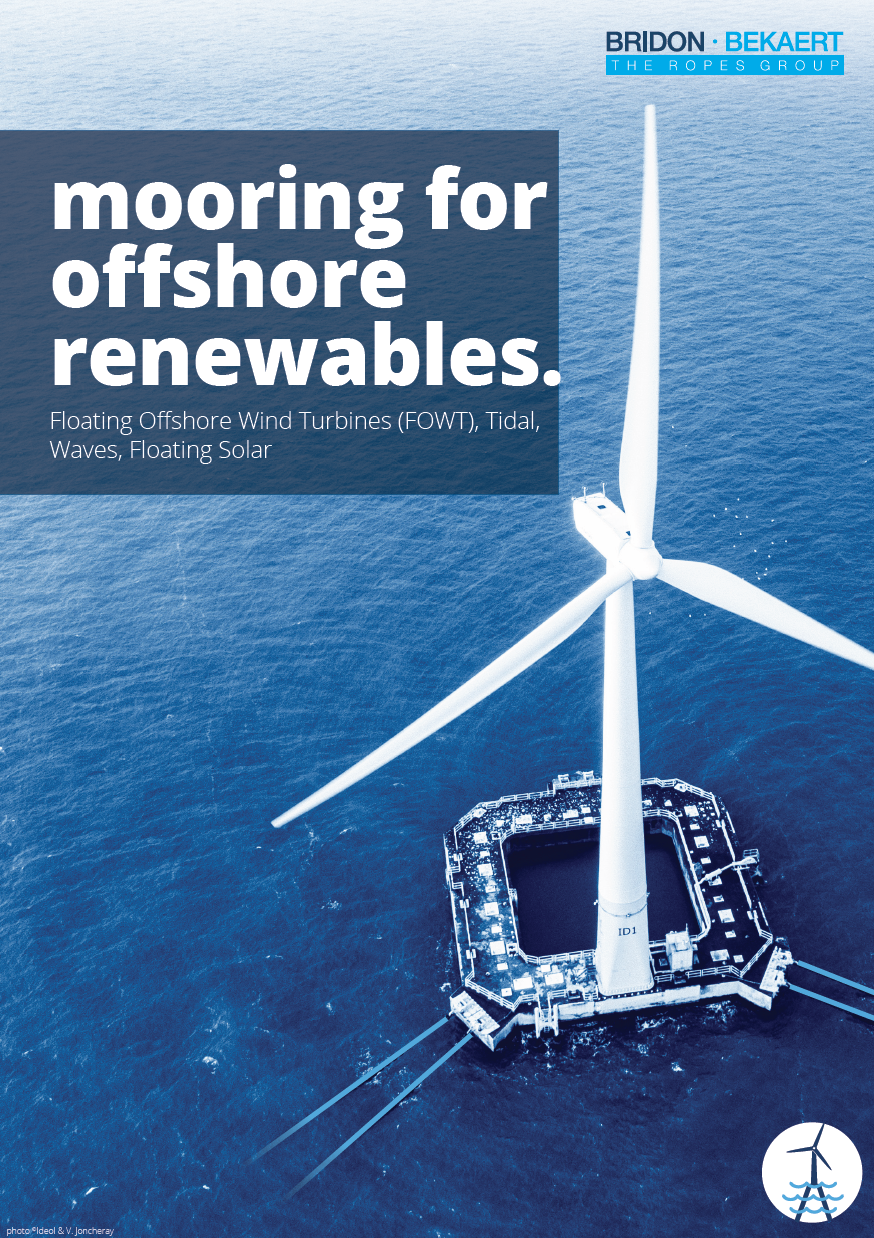

Mooring for offshore renewables

Ever since our supply of mooring lines on Exxon Lena, the first floating platform in 1983, we have continued to push boundaries, be it with the first synthetic moored truss spar (BP Mad Dog, 2004), the first floating FLNG facility (Shell Prelude, 2013), the deepest fibre spar (Shell Perdido, 2007), the first HMPE Drilling Rig Mooring (JW) Maclean, 2009) or simply the longest steel lines (SHI Egina, 2014).

Our legacy and track record shapes our unique position in serving the renewable market. For emerging applications such as floating wind, BBRG stands on its long experiencesin current mooring industries (including single point mooring, aquaculture mooring, fpso mooring, lng tanker mooring, and MODU mooring) to solve unique challenges as they develop.